Back in November of 2020, I wrote this:

COVID revealed a truth: the US is brittle. There was a need for fast, rapid action. We have a SOP for pandemics: you close the borders. The nature by which viruses spread is not magic. Instead: the media sternly fingerwags that labeling the virus by where it came from is racist, followed by social measures held in place by shaming. There is a sputtering of action at the beginning, followed by nothing but yelling about masks for 9 months.

Weaknesses do not go unnoticed. {It} happens. I can’t name what form {it} takes but {it} happens and {it} tests our institutions hard. We papered over COVID, but there’s only so much quantitative easing can do. {It} knows where to strike next time.

At the beginning of this pandemic but while toilet paper was in stock I put together what I thought was enough to get me through two months. Soon I realized I had bought 6 months worth of granola and two weeks worth of everything else. The lesson was clear: I was brittle. I relied on everything else in the world functioning properly, but there is absolutely no guarantee that that will happen.

{It} hasn’t happened yet. There’s still time to create resilient institutions. If I build them in time then when {it} hits–my guys win.

The events of last week portend the shape of {it}–Ares rises.

These beliefs were a key reason I worked at a defense startup prior to starting Ash Tree Systems. I believe in the use of machines and computers to defend America. Thankfully venture capital has come to agree and more nimble and resilient defense and manufacturing companies are being started by the day.

What I want to address today has been overlooked (as far as I can tell) in discussions of defense and American manufacturing. Let us consider the worst case scenario of total war: all industrial production is utilized in the service of defense of the United States. The global trade routes that have been the source of so many of the goods Americans buy would long ago have been severed. Metal and fuel, the lifeblood of the war machine, are in extremely high demand.

In this scenario, what is the average American’s life like? The reflexive answer is miserable, the entire production apparatus that has swaddled them their entire lives has collapsed–and it indeed will be miserable if a nullity of production takes its place.

This fate, one which would drag down the entire nation, is preventable. Defense in depth is craftsmen in their garages producing what their neighbors need. It is a culture of repair, of knitting, of antiques. It is knowing how to take something apart, fix a broken part, and put it back together again.

What blocks us from achieving this culture today? I will be the first to admit that I will often buy a replacement if something isn’t easy to fix. (I have never darned a sock in my life.) America lives in a culture of consumption. Rather than join the overwhelming amount of discourse on this topic, I will simply assume it ends due to material circumstances rather than by ideology and rhetoric.

One technology that promised to move us beyond consumerism was 3D printing: we were to start repairing our own appliances with parts we printed at home. Indeed 3D printers have become widely spread in industry–but I expect most hobbyists who bought them made a couple baby_yoda.stl prints and then left it on their shelf.

I believe a major block to more widespread use is the quality of tooling that surrounds computer-aided design and manufacture. Not that they are bad, but the exact opposite: they are so specialized that they require high levels of skill to use. A similar situation abounds in programming–and LLMs are poised to open up these skills back up to the same kind of people that were running businesses out of VBScript macros in Excel.

Thankfully CAD designs can also be expressed in terms of programs. For example, here’s one using the Python library CADQuery:

import cadquery as cq

result = (

cq.Workplane(cq.Plane.XY())

.box(4, 2, 0.5)

.faces(">Z")

.workplane()

.rect(3.5, 1.5, forConstruction=True)

.vertices()

.cboreHole(0.125, 0.25, 0.125, depth=None)

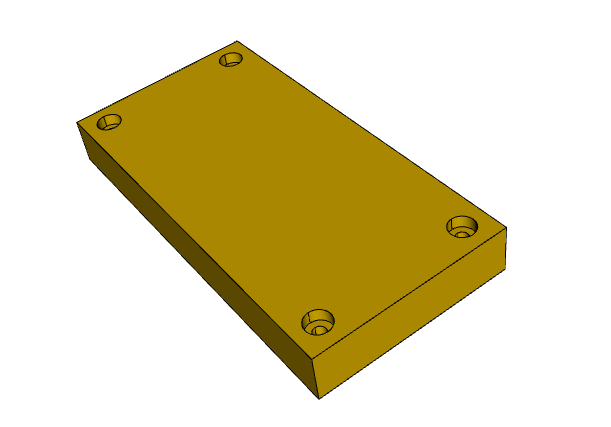

)Which yields:

That program could also be expressed as “A box of dimensions 4x2x0.5cm, with four counter-bored holes of diameter 0.125 offset by 0.5 cm.” Very few people know how to express the former program, but almost anyone can describe what they want to see in words.

This technology is almost possible today, ChatGPT kind of gets there. To truly capture the expressiveness required will require some sort of engineering tooling startup…

I think of Ash Tree Systems as a defense company that does not contract with the DoD. We cannot guarantee the American soil, but we can protect the ability for Americans to produce what they need to live fruitful lives in their garages.